Malaysia Aerospace Industry Association : Spotlight

Naguib Mohd Nor, President of the Malaysia Aerospace Industry Association (MAIA), provides insight into the current challenges facing the Malaysian aerospace sector and how MAIA advises its members and encourages industry innovation.

Cosmax Indonesia : At the Core of Asian Cosmetics

Min-Kyoung Cheong, President Director of Cosmax Indonesia, outlines the company’s integral role in catering for a rapidly growing Asian beauty market, providing tailored skincare products, halal and vegan cosmetics, and a constant awareness of consumers’ evolving needs.

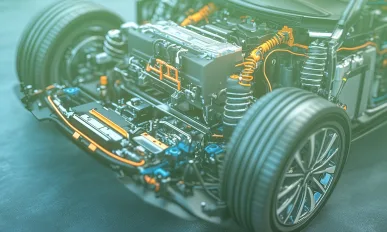

How Innovative Lubricants are Advancing Sustainability in E-mobility

In the rapidly transforming automotive sector, e-mobility stands out as a pivotal area of innovation and growth. Leyla Alieva, Co-Founder and CEO of technical lubricant manufacturer, NEOL Copper Technologies, and Professor Boris Zhmud, CTO of e-mobility startup, Tribonex AB, tell us more.

Krueger Transport Equipment : Time-Tested Quality and Excellence

We speak to Krueger Transport Equipment’s leadership team about the company’s pioneering designs, commitment to the highest standards of trailer manufacturing, and dedication to achieving customer satisfaction.

HighCom Group : Protecting the Frontline Defenders

Delving into the unmatched capabilities of the two divisions that comprise HighCom Group, we speak to Todd Ashurst, Group COO and General Manager of HighCom Technology, and Sally Nordeen, CEO of HighCom Armor Solutions.

Navantia Australia : Innovation Where it Matters

Israel Lozano, Executive Managing Director, outlines Navantia Australia’s commitment to excellence and journey to deliver a sovereign design capability for Australia.

The Drake Group : The Road to Revolutionary Innovation

Australian trailer company The Drake Group has emerged as a significant force within the country’s transport, logistics, and heavy haulage industry, providing high-quality and wide-ranging products and services.

MTM Pty Ltd : Precision and Strength

Driven by the desire to pursue comprehensive functionality embodied in simplicity, MTM Pty Ltd’s automotive innovation prioritises ease of assembly. Mark Albert, CEO, tells us more about the global automotive supplier.

Kongsberg Defence Australia : Delivering World-Class Technology Systems

Manufacturing world-leading technology for the Australian Defence Force, Kongsberg Defence Australia is working together with industry partners and key suppliers to deliver proven and effective systems to both the Australian Army and Royal Australian Navy.

Supashock Advanced Technologies: Supplying Stability

Pursuing originality, which often results in globally recognised innovation, Supashock Advanced Technologies’ mobility systems are improving vehicles in various industries. CEO, Oscar Fiorinotto, discusses design, defence, and development.