With care, integrity, and excellence at the heart of every project it undertakes, Sanfield (Management) Limited is committed to building a safer, more sustainable, and future-ready construction ecosystem for Hong Kong. Eddie Ho, Deputy General Manager, reflects on the company’s evolution within the context of the wider industry and its goals for the future.

BUILDING HOMES WITH HEART

Over the past three decades, Hong Kong’s construction industry has transformed from a hub of rapid post-war urbanisation to a global leader in high-rise, high-density construction, embracing digitalisation and sustainability.

From the 1980s-90s, the industry became defined by its innovative land reclamation and slope stabilisation techniques, enabling dense urban development and establishing Hong Kong as a global benchmark for high-rise construction.

“My work on structural engineering projects during this period honed my skills in designing resilient, compact structures,” opens Eddie Ho, Deputy General Manager of Sanfield (Management) Limited (Sanfield), the construction arm of Hong Kong’s leading property developer Sun Hung Kai Properties (SHKP).

The 2000s marked a shift towards iconic, larger-scale projects, during which time Ho worked on the International Commerce Centre (ICC) – a 490-metre (m) super high-rise skyscraper that pushed the boundaries of structural steelwork and vertical construction.

During the 2010s, the industry began to adopt digital tools like building information modelling (BIM) and modular integrated construction (MiC), allowing for faster, more sustainable builds.

As it entered the 2020s, SHKP – like many other companies – was faced with socioeconomic challenges such as the COVID-19 pandemic and the property market headwinds.

However, SHKP continued to invest and Sanfield continued to participate in the construction of several landmark projects, such as the High Speed Rail West Kowloon Terminus Development, helping to fuel the city’s recovery.

Recent years have seen the industry push towards sustainability and integration with the Greater Bay Area (GBA), whilst digital transformation and workforce upskilling have also improved conditions.

“At Sanfield, we’ve prioritised low-carbon construction methods and explored opportunities to develop more vibrant communities in the city, aligning with the nation’s long-term urban vision,” Ho confirms.

INFUSING CARE, INTEGRITY, AND EXCELLENCE

As a subsidiary of SHKP, Sanfield provides a vast portfolio of construction and engineering services, including site formation, civil engineering, building construction, mechanical, electrical, and plumbing (MEP) systems installation, and interior decoration.

It also offers landscaping, electrical and fire-prevention systems, and supplies of ready-mix and precast concrete.

Primarily serving SHKP as its construction division, Sanfield caters to residential, commercial, and comprehensive development projects.

Operating from within SHKP’s headquarters in Wan Chai, the company oversees projects both in Hong Kong and on the mainland, supporting SHKP’s real estate developments and select third-party clients with a focus on quality and safety.

SHKP’s motto, ‘Building Homes with Heart’ – also Sanfield’s – reflects its commitment to infusing care, integrity, and excellence into every project it undertakes.

“Our motto underscores our dedication to quality by prioritising precision, safety, and sustainability in construction, ensuring all projects are safe, functional, and enduring,” Ho prides.

This ethos guides Sanfield’s relationships with its clients, subcontractors, employees, and suppliers by fostering trust, collaboration, and mutual respect.

“We embody our motto through transparent communication, rigorous quality control, and community-focused initiatives,” he adds.

For example, Sanfield’s Warm Companionship Day partnered with the Construction Charity and Caring Centre (CCFISC) at GO PARK Sai Sha, providing assistance to families affected by construction accidents and creating a mutual support platform through various engaging activities.

The event featured a rewarding beach clean-up and chances to try exhilarating new sports, empowering families to uplift one another, share their unique journeys, and rebuild their confidence as they move forwards together.

Its dedicated Sanfield Connect volunteer team was also on hand to provide guidance and assistance throughout the event.

The company hopes initiatives like this raise awareness for families affected by construction accidents and highlight the critical need for workplace safety.

“We deliver everything we undertake with passion, aligning with our mission to create lasting, meaningful spaces across all projects.

“By engaging in charity and community support, we promote inclusivity, enhance well-being, and contribute to vibrant, resilient neighbourhoods,” Ho reflects.

These efforts align with Sanfield’s values of responsibility and care, ensuring it creates positive impacts, strengthens trust, and nurtures environments in which people thrive, reinforcing its role as a dedicated community partner.

THE BACKBONE OF DIGITAL CONSTRUCTION

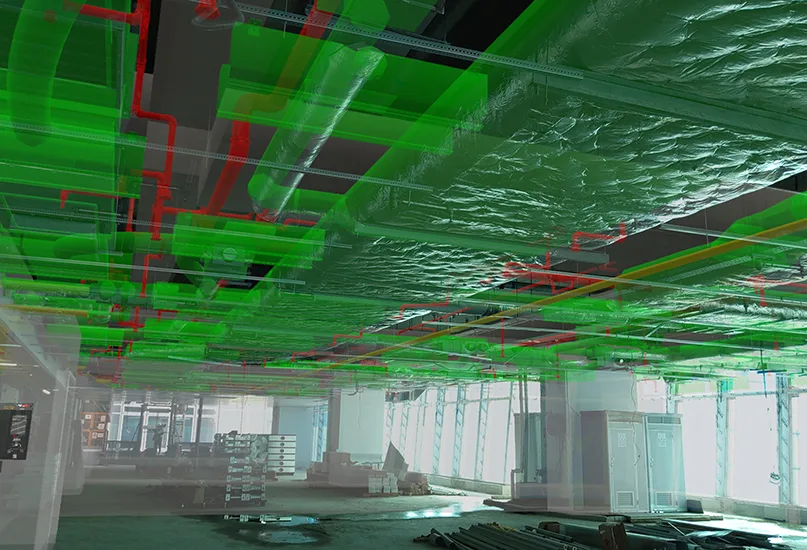

As a forward-thinking contractor, Sanfield leverages BIM as a central digital framework to drive efficiency, collaboration, and smarter decision-making across all project phases.

“By integrating advanced technologies and data-driven workflows, we transform traditional construction phases into streamlined, risk-mitigated operations that enhance project delivery,” Ho outlines.

During the preconstruction and design coordination stage, Sanfield employs artificial intelligence (AI)-driven clash detection technology to automate conflict resolution, thus reducing manual review time by 30 to 50 percent.

This is complemented by generative design techniques which optimise structural and MEP layouts for offsite fabrication, ensuring constructability from the earliest stages.

Additionally, 4D and 5D BIM simulations enable Sanfield to link schedules and cost data in real time, allowing teams to run scenario analyses and proactively address potential delays or budget overruns before commencing the project.

“Once on site, BIM becomes the backbone of digital construction,” he states.

Deploying augmented reality (AR) tools such as Microsoft HoloLens for layout verification and quality assurance allows the company to minimise rework, whilst Internet of Things (IoT)-enabled tracking – including radio frequency identification (RFID)-tagged materials – ensure just-in-time delivery and real-time progress monitoring.

“For precision, robotic total stations automate field layouts directly from BIM, achieving sub-centimetre accuracy and eliminating human error,” Ho details.

To maintain tight project controls throughout, Sanfield also implements digital twin technology, where live data from drones, 3D laser scans, and BIM creates an evolving model.

This, paired with predictive analytics dashboards such as Microsoft Power BI to forecast delays and resource needs, enables proactive adjustments.

Sanfield also maximises efficiency through lean methodologies off-site, including design for manufacturing and assembly (DfMA) principles, which allow it to standardise modular components and cut on-site labour by 20 to 40 percent.

Integration between BIM platforms and enterprise resource planning (ERP) systems, meanwhile, can further streamline procurement and logistics.

For stakeholders, immersive 3D models facilitate interactive design reviews and safety training, whilst cloud-based collaboration tools keep all parties aligned with live issue tracking.

“As a result, our innovative BIM approach delivers 15 to 30 percent faster project timelines via clash-free models and prefabrication, five to 10 percent cost savings through waste reduction, and higher-quality, safer builds enabled by AR validation and digital twins,” he insights.

“By integrating advanced technologies and data-driven workflows, we transform traditional construction phases into streamlined, risk-mitigated operations that enhance project delivery”

Eddie Ho, Deputy General Manager, Sanfield (Management) Limited

A DISTINCT EDGE

Having made strategic investments in emerging technologies to enhance safety, efficiency, and adaptability across its operations, Sanfield sets itself apart.

One key area in which such investments have been made is in the adoption of smart tower crane systems to support the growing trend of MiC.

Typically, the installation of MiC units – particularly large modules – requires between four and six ground workers manually handling taglines, which is not only labour-intensive and time-consuming but also exposes workers to significant safety risks.

“To address this, we developed and deployed a remote-controlled smart tower crane system by integrating automation and remote operation capabilities,” Ho tells us.

Sanfield’s solution significantly reduces the need for manual intervention and improves installation efficiency by over 50 percent, creating a safer environment by removing workers from high-risk zones.

“This investment delivers short-term productivity gains and gives us a distinct edge in adapting rapidly to the evolving needs of the construction industry,” he excites.

Ultimately, this undertaking aligns closely with the company’s broader goal of building a safer, more sustainable, and future-ready construction ecosystem.

ARTIST SQUARE TOWERS

Situated within the West Kowloon Cultural District, the Artist Square Towers (AST) project comprises three commercial towers – P31, P32, and P34 – featuring a striking architectural design in which P31 and P34 are interconnected 50m above ground.

Serving as a transport gateway for the link bridge extending from Kowloon Station, the structure enhances connectivity within the local area.

However, the project has not been without its challenges. Due to the four fully operational metro railway tracks and public spaces located directly below the AST site, open-air construction work was initially prohibited.

Therefore, Sanfield engineered P31 and P34 to overcome these unique spatial constraints, creating 60m-high steel mega trusses between the towers to enable work to continue.

Indeed, a steel platform above the railway serves as both a protective shield and an innovative design element. The platform is divided into 16 segments – each assembled on-site, lifted into place, and connected together – minimising disruption and requiring just an hour of public area closure per segment.

Meanwhile, a second identical steel platform supporting the mega truss acts as a safety barrier, ensuring stability during the erection.

“Through our innovative construction design, we have been able to safeguard the link bridge and public spaces below the AST site whilst assembling mega steel trusses,” Ho surmises.

FUTURE FOCUS

Dedicated to excellence in construction, innovation, and sustainability, Sanfield has strategic priorities and goals in place to help it achieve this today and in the future.

Delivering high-quality projects that align with its motto, the company seeks to ensure superior craftsmanship, safety, and customer satisfaction.

“In doing so, we can maintain our leading position in Hong Kong’s construction industry, implementing rigorous standards across all project phases,” Ho informs.

Sanfield is also dedicated to supporting Hong Kong’s and China’s carbon neutrality goals by integrating smart building technologies and sustainable practices.

“We are actively trying to reduce our environmental impact through high-productivity methods such as those demonstrated at the Global Construction Sustainability Forum.”

The company also strives to uphold the highest safety standards and optimise project timelines by advancing its processes whilst investing in its workforce and communities through participating in programmes such as the government’s Strive and Rise, which empowers underprivileged youth.

Going forwards, Sanfield will continue to leverage SHKP’s vertical integration strategy to optimise its processes and is poised to grow its market presence and service offerings by building on its expertise.

The company will also continue to expand its services for third-party clients in Hong Kong, developing its market growth by exploring opportunities in specialised construction sectors such as commercial and infrastructure.

By adopting cutting-edge technologies, diversifying operations, and advancing its smart building technologies, Sanfield demonstrates its commitment to sustainable growth, technological advancement, and community impact.

“Aligning with SHKP’s vision, we aim to deliver exceptional projects, expand our market reach, and contribute to Hong Kong’s built environment,” Ho passionately concludes.