We revisit mineral drilling contractor Swick Mining Services, whose executive team reflect on the company’s growth story over the past two years.

SOUND OF THE UNDERGROUND

It was a record-breaking FY25 for Swick Mining Services (Swick), a leading provider of drilling services across a wide spectrum of commodities.

The company maintained its full client base and secured all contract extensions and renewals, according to Business Development Manager, Robert Burnett, who we last spoke to in June 2023.

“Swick achieved a 21.43 percent increase in drill metres, rising from 1.4 million in FY24 to 1.7 million,” he updates us.

Moreover, its operating sites grew from 22 to 27, supported by an increase in personnel from 753 employees to 907.

Swick, which is now part of the Perenti group of companies, also expanded internationally, successfully entering Canada with the deployment of two rigs under new client contracts.

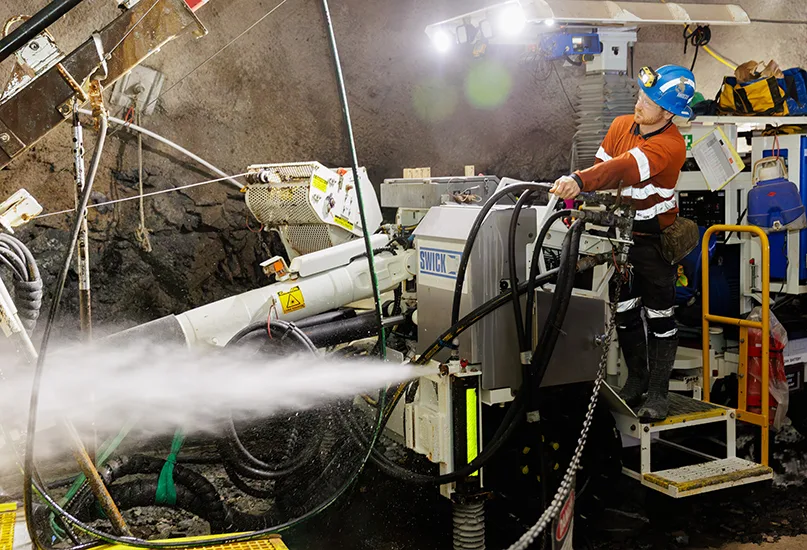

DRILLING OPERATIONS

Strategically, the company reinforced its gold-focused operations in FY25, with 45 percent of sites operating in this commodity, supported by favourable market conditions.

As well as gold, the commodities Swick actively supports include copper, nickel, cobalt, lithium, tin, zinc, lead, silver, and uranium.

Each of these presents unique geological conditions that influence drilling methodology, equipment selection, and operational planning.

“Swick’s strategic engagement with clients is underpinned by a deep understanding of their operational priorities and the geological complexities associated with each resource,” Burnett outlines.

“Our approach is both adaptive and data-driven, ensuring optimal performance and safety across varied terrains and mineral profiles.”

The company’s drilling operations are tailored to meet the specific demands of each commodity, with techniques refined to address hard rock formations, reactive and moisture-sensitive environments, deep and structurally complex ore bodies, and soft sedimentary layers.

Swick’s engineering and field teams continuously innovate to overcome these challenges, leveraging proprietary rig designs, real-time data acquisition, and rigorous safety goals.

Strategic client positioning also ensures the company remains aligned with both short-term project goals and long-term resource development.

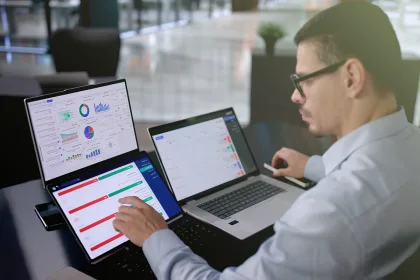

“This includes customised drilling programmes based on commodity-specific exploration and production targets, integrated reporting and analytics to support client decision-making and regulatory compliance, and collaborative planning to optimise rig deployment, reduce downtime, and enhance cost-efficiency,” Burnett tells us.

DEEPEX INVESTMENT

Swick further advanced its technology portfolio in FY25 with investment in DeepEX rigs capable of drilling up to 3,000 metres (m) and large diameter infrastructure holes, providing significant opportunities to clients.

There was a time when the demand for exploration was a lot higher, especially in hole depths of over 1,000m.

However, Swick wasn’t widely known or perceived by the market as being in that space, even though its rigs and personnel were more than capable of doing those types of holes.

The company therefore ended up investing in DeepEX to modify its mobile rig to drill even deeper than its standard rig.

“We’ve used the same people within that, and it’s been a very successful part of our business. It’s a small offering we have there but more and more clients are looking at it,” shares Nick Rossides, General Manager.

DeepEX continues to expand the company’s capabilities in underground engineering, delivering innovative, high-precision solutions tailored to the evolving needs of the mining and geotechnical sectors.

With an operational range effective from -90° to +45° angles, it executes precision breakthrough drilling into underground voids to facilitate Cavity Auto-Scanning Laser System (C-ALS) surveys.

This real-time mapping technology enables accurate measurement of void dimensions, muck pile propagation, and stope or cave geometry.

“DeepEX enhances stope management, supports backfill planning, and improves safety through better void visualisation,” elaborates Burnett.

Its engineering scope also includes seismic smart marker installations in high-activity ground zones, which can be spaced as close as 50 centimetres apart.

These sensors transmit live geotechnical data to engineering teams, enabling predictive modelling of seismic events and cave behaviour, proactive risk mitigation, and real-time geotechnical monitoring.

“DeepEX also drills and installs stress cells to monitor in-situ stress conditions, supporting structural integrity assessments and mine design optimisation,” Burnett notes.

The rigs additionally provide high-precision drilling for critical underground infrastructure, including drainage systems, electrical and communication cabling, and paste fill lines, which reduces installation time and ensures alignment with mine service layouts.

“Underground infrastructure drilling allows the mine to continue growing and service other areas,” Rossides affirms.

Equally, rigs are equipped to safely drill into and continue through large underground voids, supporting exploration, ventilation, and infrastructure expansion.

“DeepEX rigs are engineered for versatility and performance, with drilling strategies such as top-down collar, bottom-up, and custom fit-for-purpose equipment,” Burnett informs.

“This flexibility ensures compatibility with a wide range of underground applications, from instrumentation to service line installation.”

“DeepEX enhances stope management, supports backfill planning, and improves safety through better void visualisation”

Robert Burnett, Business Development Manager, Swick Mining Services

UPSKILLING DRILLERS

Alongside its investment in DeepEX rigs, Swick is committed to operational excellence through its comprehensive Driller Training Programme, which is designed to upskill, retain, and develop the next generation of drilling professionals.

The programme’s initiatives begin at Swick’s training facility located in Perth, Western Australia (WA).

This facility provides a controlled environment where new recruits are introduced to the fundamentals of drilling operations, safety protocols, and equipment handling, ensuring they are well prepared before stepping on site.

“Once in the field, training continues through a hands-on, engaging experience led by our dedicated technical trainers, alongside experienced offsiders and drillers,” reveals Chris Loo, Operations Manager.

“This on-site mentorship model ensures that learning is continuous, allowing new team members to build their skills and capability in the role.”

The collaborative environment fosters knowledge sharing and reinforces a strong safety culture, which is critical to Swick’s operational success.

To formalise and recognise the skills acquired, all offsiders are enrolled in the Certificate II in Drilling Operations, whilst drillers progress through the Certificate III and IV qualifications.

“These nationally accredited certifications not only validate technical proficiency but also provide clear career pathways within the business,” Loo highlights.

“By investing in structured learning and professional development, we not only enhance workforce capability but also strengthen employee engagement and retention, ensuring our teams are equipped, motivated, and ready to meet the challenges of modern drilling operations.”

“Once in the field, training continues through a hands-on, engaging experience led by our dedicated technical trainers, alongside experienced offsiders and drillers”

Chris Loo, Operations Manager, Swick Mining Services

EXPERTISE AND EXPERIENCE

Another aspect of Swick’s operational excellence is the expertise and experience of its employees, with around 15 percent of the workforce having been at the company for 10+ years.

Since 2023, the organisation has experienced significant growth in staffing, with the current headcount exceeding 730 direct hires across Australia.

This expansion reflects a strategic focus on building internal capability whilst leveraging the support of several labour hire businesses.

“The collaboration between direct employment and labour hire partners has proven highly effective, enabling flexible workforce balance and ensuring operational continuity across all sites,” Loo observes.

A strong focus has been placed on upskilling Swick’s supervision and management personnel through a range of targeted training programmes, including the implementation of the Leadership Development Programme.

The programme is designed to enhance leadership capability and support professional growth across the organisation.

“Additionally, in-house programmes like the Introduction to Supervision training and the redeveloped Drilling Fundamentals course are tailored to support the development of drillers, reinforcing technical proficiency and operational excellence,” states Loo.

COLLABORATIVE EFFORT

Swick’s maintenance and engineering teams play a critical role in ensuring mechanical availability remains paramount across all operations.

Their support is instrumental in driving the performance and growth of both new builds and rebuilds.

With the capacity to build multiple rigs through their workshops, the teams are focused on delivering high-quality, reliable equipment ready to meet demands in the field.

Swick also has teams that focus purely on specialised programmes for specific customer requirements and can be deployed to certain sites.

“It might be a one-off programme that the client asks for, so we have specific teams we can send. The same can be said for our operations, management, and even health, safety, and environment (HSE) teams,” enlightens Rossides.

“All these people have come from an operational background within Swick, so they’ve actually experienced that type of work and have the solutions. It’s not just something they’ve read – they’ve actually lived it themselves, which goes a long way in terms of what our clients expect, so that’s been a very big part of our success story.”

“I’ve been with the company for nearly 20 years, and when I started, we had three drill rigs. We’ve now got 84 operating globally, but we still instil that family feel”

Nick Rossides, General Manager, Swick Mining Services

COMPANY CULTURE

Whilst being one of the world’s largest mineral drilling contractors, specialising in underground diamond coring, Swick has always held onto and maintained its family values.

“I’ve been with the company for nearly 20 years, and when I started, we had three drill rigs. We’ve now got 84 operating globally, but we still instil that family feel,” Rossides prides.

“We’re very big on rewarding and promoting the good work that our people do. It’s not just a case of here’s your pay and away you go – we’re quite flexible in our work rosters and very family-orientated.

“We include families in a lot of things we do. That’s a priority for us because we know they support our people back home, so we’re very mindful of celebrating families and try to do that as much as possible,” he continues.

Keeping the family feel of the business goes a long way and isn’t limited to what Swick does out in the field, as everyone in its corporate offices also has the same attitude.

“We all roll our sleeves up and get stuck into the work. Everyone’s very invested in what we do to see the business succeed.”

Along with family, safety and being solutions-focused are important values for Swick, with the latter something the company has always driven to uphold.

Innovation is the biggest thing the company is known for, having designed the first true underground mobile rig.

“That was a big innovation in itself, but we also look at the way we work, the applications we put in place, the way we treat our people, and our systems as innovation as well,” acclaims Rossides.

“We’re very big on taking innovation from the field, so those that are working on the rigs will come up with some of these solutions. We design what we can in-house to better the rigs themselves and make them safer and more productive,” he concludes.

SWICK MINING SERVICES PARTNERS