The Automation Fair event, hosted by Rockwell Automation and members of its partner network on 15-16 November, 2017 in Houston, Texas offered a number of announcements of new end user developments and advanced capabilities available to Rockwell Automation customers, including the FactoryTalk software and the Studio 5000 environment.

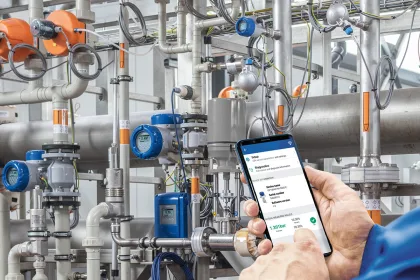

The Rockwell Automation vision of The Connected Enterprise continues to gain traction within the company’s customer base, with Rockwell Automation CEO, Blake Moret, commenting: “The Internet of Things is unlocking new ways of gaining value and increasing productivity, and we are just getting started. The Industrial Internet of Things connects data: we take the data from those plant-floor devices and turn it into useful information and produce positive outcomes for our customers. Good things happen when we combine the potential of automation with the imagination of people.”

Three major new advances were demonstrated for the company’s FactoryTalk software offering, including two recently commercialised offerings, FactoryTalk Analytics for Devices and FactoryTalk Analytics for Machines, as well expanding the FactoryTalk Analytics Platform with Project Scio, a broader advanced analytics capability currently under development.

These advances aim to create a deeper ability to organise and orchestrate disparate data sets and drive stronger operational insights in real time. The result is an, open, scalable analytics platform that allows plant teams to scale across the entire information architecture and a move for organisations away from more descriptive and diagnostics-based analytics into the realm of predictive and prescriptive analytics. This allows decisions to be made closest to the source of the data, where they can have the biggest impact on results.

In addition, three new capabilities were announced for the Studio 5000 environment, including:

· AutomationML Interface enables bi-directional exchange of data with other tools like EPLAN and other CAD systems

· Improved interface for emulation environment so users can conduct operator training with other systems

· The newly-branded FactoryTalk Linx, formerly RSLinx, a communications software used with the Rockwell Software portfolio, supports OPC-UA open unified connectivity

Joseph Sousa, president, Asia Pacific, Rockwell Automation, noted: “Developments that offer enhanced connectivity and access to information in new and existing assets are crucial as Rockwell Automation helps its customers achieve the vision of smart manufacturing. These new advances will offer our customers in APAC and across the rest of the world greater analytics power and the ability to get deeper insights into their business in order to improve resiliency in the face of changing market conditions.”