Vitrinite is focused on utilising an untapped tool in its open cut mines. We speak to Michael Callan, COO of the company, about the latest developments across the Vulcan Mine Complex.

HEADING UP THE HIGHWALL

The industry has gone through quite a tumultuous past year – it has been a bit of a wild time. We had coal prices going into the 600s during the middle of 2022, which is both incredible and unsustainable.”

Coal is a global power source responsible for around 36 percent of the world’s electricity. Metallurgical coal, more commonly known as coking coal, is used to produce coke, an essential fuel for many modern industries such as steel production. It therefore comes down to coal mining companies to fuel this global requirement.

In Australia, the mining sector is one deeply embedded in the country’s past, and coal is no exception. Yet despite its historical roots, there are new companies making their mark in an old industry, leading with dedication and technological savvy.

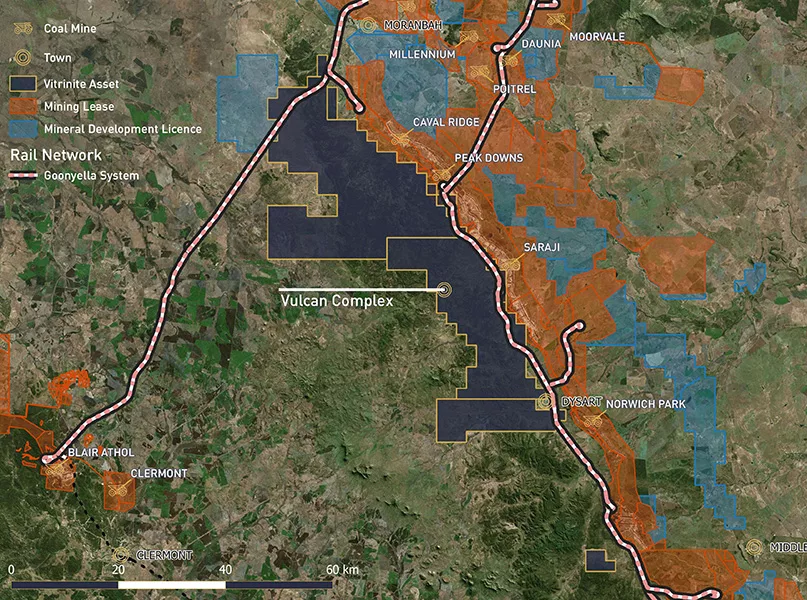

Vitrinite is one of these active and innovative companies, privately owned and holding an extensive strategic coking coal tenement portfolio within Queensland’s world-class Bowen Basin. At present, Vitrinite is primarily focusing on the well-known Vulcan Mine Complex (Vulcan). The company’s assets are situated in close proximity to operating mines, infrastructure and proven economic resources. Vitrinite is undertaking extensive exploration efforts within its holdings, identifying new deposits of premium coals in the basin.

Vitrinite is a young, progressive company insisting on excellence in every aspect of its work, and takes immense pride in the coal industry and the Australian resources sector. Vitrinite ensures stewardship of the lands and developing mineral deposits, aiming to achieve outsized returns for its shareholders and stakeholders.

The company’s values embody and encourage an open and collaborative attitude, inward and outward, while its vision is to create value and wealth through the provision of energy to power world economic growth, exceeding and setting world’s best practices in every endeavour.

“Costs have risen, dropped and stabilised after major fluctuations. This stability in price spells good times ahead for Australian coal, particularly coking coal,” introduces Michael Callan, COO of Vitrinite and orator of the opening statement.

“On top of this, there are industry-wide changes and scrutiny around gaining approval for projects, especially when looking at a federal level, although it is slightly easier for coking coal.”

THE VULCAN MINE COMPLEX

Vitrinite is soon to be celebrating its ninth birthday, with 2023 also marking two years since the company first produced coal in the Vulcan region. For the past year, Vitrinite has been ramping up production to full capacity, including preparation work for the transition from its Jupiter pit, as well as focusing on other areas of the mining complex.

“We started Vulcan activities in June 2020, including preparation work, with the first coal production starting in September 2021, so we have been producing coal there for two years out of the open cut pit,” Callan tells us.

“It is a really exciting time at the moment. Our ramp-up includes expanding the complex to operate in an additional area.”

This new location is Vulcan South, a mine in the pre-approval phase awaiting process completion for Vitrinite to move forward with mining operations. Separate from the Jupiter area, Vulcan South is still part of the greater mining complex, located only nine kilometres (km) from the Jupiter pit.

Vulcan South is not only a new area of coal exploration, but it also represents a significant transition that will see Vitrinite’s industry-leading knack for innovation taking centre stage.

“We are looking to transition from Jupiter and end the life of that mine, and to move on to Vulcan South which is another open cut operation based, as per the name, in the south of the complex. This will involve transferring the same workforce to that location as well,” Callan explains. “This is the next big step for us at Vitrinite; it’s the next mine within the Vulcan complex that we are going to be exploring and working on.”

This development consists of completely separate mining approvals and processes. According to Callan, the primary point of excitement within the project is the introduction of new and industry-innovative technology at the new site.

“We are introducing a highwall miner into our production at Vulcan South,” he reveals. “Like the Jupiter site, Vulcan South is an open cut mine similar to its soon-to-be predecessor, utilising similar mining equipment and run rates. However, we will be the first in Australia to use a highwall miner and prove its effectiveness, and we foresee this setting a trend that will echo through the industry.”

“It is a really exciting time at the moment. Our ramp-up includes expanding the complex to operate in an additional area”

Michael Callan, COO, VITRINITE PTY LTD

MAXIMISING MINING POTENTIAL

Highwall mining is not a brand-new notion; in countries such as India and the US, highwall miners are used in standalone mining operations to extract mineral deposits left over from primary mining activities.

Vitrinite has entered a contract with global supplier Gainwell Engineering Global Pte Ltd (Gainwell Engineering), to receive a GHWM300M Highwall Mining unit to support activities at Vulcan South. The equipment is manufactured by Caterpillar Inc (Caterpillar), a world leader in construction and mining equipment, among many other industrial technologies and engines.

When primary open cut (or other) mining takes place, activities contour and follow seams in the earth to extract mineral wealth until only small deposits are left over. This primary extraction inevitably creates a growing subcrop at a site, such as a hill for example, that makes mineral extraction from the remaining thinner coal seams more difficult and require a more technical solution.

“What we intend to do is bench out the subcrop area exposing the fresh coal at a geotechnical stable depth to allow the highwall miner to be positioned at the fresh coal face on the newly created bench,” Callan shares. “The highwall miner, a remote-controlled underground roadway miner pushed underground without personnel, is used to take further amounts of coal from thinner seams at a separate and standalone site, where traditionally people would operate machinery that goes underground.”

To be the first of its kind used in Australia, the introduction of highwall mining technology will play a significant role in the future of the nation’s mining industry, as it has in many other coal markets around the world. On top of being notably productive by providing access to coal that would otherwise be stranded, highwall miners have proven to be safe, with a low environmental impact. However, the potential of this equipment has thus far not been recognised.

“It is the reputation of this equipment being used for scavenging projects that has prevented its incorporation into Australian mining,” Callan elaborates. “A national industry that traditionally leans towards primary mining activities, mining companies view pursuing further extraction via highwall mining as unnecessary and not worth the time and financial investment.

“Utilising highwall mining is unsuccessful in Australia due to this association, being seen as a major primary mine activity effort for limited reward, instead of being viewed as a side project.”

For Vitrinite, this is exactly what highwall mining will represent. While primary open cut mining activities will be carried out at the new Vulcan South site, highwall mining will act as a secondary side operation to maximise yield.

“The way we are doing it, the emphasis we are putting on it and the style with which we are using it can be considered somewhat novel in the industry,” Callan states. “Elsewhere, highwall miner tech is used routinely, and it is often used as a side project – installed towards the end of a project to retrieve the last traces of coal.

“The way we are using it is similar to how they utilise the technology in the US; we consider use of the highwall miner a project in itself, not a side project, and it will form a key proportion of our total overall mine production.”

OPEN CUT EXPANSION

Vulcan South represents a new frontier for Vitrinite, and marks the company’s focus on the expansion of open cut operations moving forward into 2023 and beyond. The introduction of highwall mining is a key focus point in this growth, opening up a promising new production and revenue stream for the company while proving the worth of the technology to the entire industry.

“The investment into this highwall miner is key for us and is the future of the mine, being a piece of equipment that has not operated in the country before, and working with the different legislation and compliance requirements,” adds Callan.

“What is equally as important to our continued growth and success is our many partners, suppliers and business relationships that keep us going, and help us achieve success.”

For Vitrinite, a selection of key contractors and suppliers is vital in the industry, and the company’s partners are critical to its operations. This is best exemplified by the company’s mining and haulage contractors, made up of multiple small family-owned businesses local to the Queensland region and familiar with Vulcan territory.

“We love bringing people with us on our journey and helping build these companies via our operations,” Callan tells us proudly. “Directly dealing with owners of those companies is important, as is maintaining these relationships. Although we are not the largest mining company out there, we are starting to get to the scale of operation whereby smaller companies are relying on us to keep work flowing.

“Another great part of working with smaller local partners is the culture aspect of work; everyone shares a similar inclusive mindset and we bond as if we were one team. Key suppliers have the same ethos as us, so it becomes very easy for us to mesh cultures together and work effectively while enjoying what we do day to day.”

There are certainly exciting times ahead for the company. As activity at the Jupiter pit comes closer to its end, and the gradual transition to open cut operations progresses at Vulcan South alongside the incorporation of highwall mining technology, preparation for such a future is the core of current affairs at Vitrinite.

“The most exciting thing is getting prepared for this transition, and it is not just about buying equipment and getting it set to work,” Callan explains. “There is a lot of work to do in regard to setting up systems, getting prepped for it, and working with the original equipment manufacturers (OEMs) to get the construction and design completed on time, and getting it delivered.

“On top of all this, we are recruiting a team at the moment to run this, so by the end of 2023 we will be ready to accept delivery of that and fully transition over to Vulcan South and ever more prosperous years ahead at Vitrinite.”