Driven by a mission to become the partner of choice in delivering comprehensive maintenance solutions, CR Asia Group is uplifting industries, communities and people alike across the continent with its customer-centric contracting.

A MULTI-DISCIPLINED MAINTENANCE MASTERMIND

The morning of June 23, 2018 was a special occasion, albeit a relatively ordinary day, for Peerapat ‘Night’ Sompiangjai – a 17-year-old boy living in the Thai village of Chiang Rai, two hours’ drive southwest of Bangkok.

Turning up to football practice for local youth team the Wild Boars as he usually would on a Saturday, his coach and 11 teammates raced their bikes up through a trail between rice paddies to the Tham Luang cave – a nearby haunt that they often explored.

Stashing their bikes and bags by the cave entrance, the group of friends clambered in with just their torches and some snacks, planning to spend only an hour celebrating Night’s birthday there before heading home. Little did they know that they would not emerge until two weeks later.

After locals discovered the unclaimed belongings at the cave entrance, authorities scrambled to organise a full-blown rescue operation, calling in the elite Thai Navy Seals, specialist cave divers, police, soldiers, other rescue workers and various government agencies and companies, including CR Asia Group.

Responding to this call to action without hesitation, CR Asia sent a series of specialised submersible pumps to Tham Luang to extract the muddy floodwaters, and five kilometres of air hoses and special low-pressure regulators to provide oxygen to various chambers in support of the rescue mission.

After several days the water levels had reduced, and oxygen levels had increased enough that the rescue teams and divers were able to venture far enough into the cave, discover the football team perched within a rocky alcove and ensure their safe rescue.

“After a gruelling 18-day battle against the forces of nature and a huge international rescue effort, the last of the 13 Wild Boars were extracted from the Tham Luang Cave to jubilant scenes broadcast live around the world,” states David Young, CR Asia’s Group Business Development Manager.

“We are immensely proud to have been a part of this huge international rescue team.”

By no means a specialist in cave rescues, the company was called in owed to its diverse array of industrial expertise and equipment that would undoubtedly prove to be crucial to the rescue teams’ efforts.

These same assets remain crucial to a vast number of asset-intensive industries across Asia, the company firmly established as one of the region’s preeminent execution contractors.

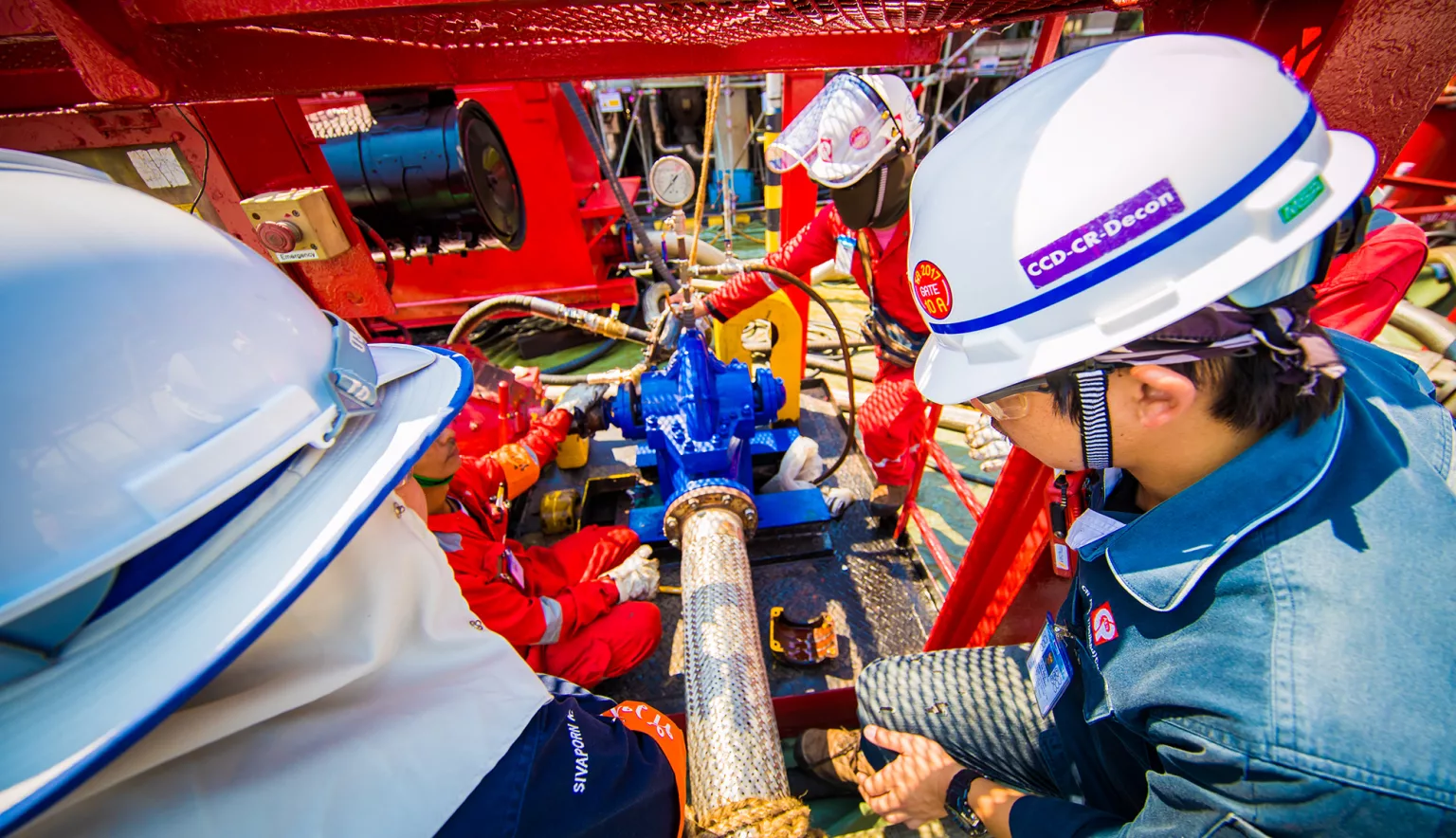

“CR Asia is all about bringing people and technology together to get any job done,” says Young, “whether that’s assisting a cave rescue or delivering comprehensive maintenance solutions to the oil, gas, refining, petrochemical or power sectors.”

Indeed, it is the latter that constitutes the bulk of CR Asia’s business.

Operating from its four key bases in Thailand, Singapore, Malaysia and India, the company’s multi-skilled, motivated team and high-quality systems, procedures and equipment deliver everything from mechanical and plant maintenance, chemical cleaning and catalyst handling services to pipeline and process services, and shutdowns and turnarounds.

“We offer many solutions that would normally have to be subcontracted by large maintenance management companies,” Young reveals. “We believe that our ability to plan, manage and execute maintenance activities, rather than just managing teams of subcontractors, is what sets us apart and provides added value to our customers.

“Our business philosophy is to always work collaboratively with our customers, and we have a reputation for honesty, openness and flexibility.”

This customer-centric approach is a fundamental part of the company’s overriding ethos and is one of the reasons why a significant portion of CR Asia’s work is derived from repeat business and loyal customers.

It works closely with each client, aligning both parties’ goals to establish clear objectives and a transparent, trust-based working environment. Thereafter, combining collaboration with continual investments in the best equipment, systems and performance management tools and a large in-house team of highly trained technicians, CR Asia consistently delivers the highest standards of safety, efficiency, productivity and customer satisfaction.

“Our main objective is to become the partner of choice in each of our disciplines,” Young explains. “Our commitment to service excellence is underpinned by our integrated approach to safety, quality and the environment as well as our continual investment in developing our people and securing the latest technology available.

“We pride ourselves on delivering safer, faster and more efficient results. With each operational success, the experience and knowledge gained is channelled into the next generation of solutions.”

At this point, Young takes the opportunity to showcase a few highlights of CR Asia’s extensive portfolio, first pointing to a major ongoing contract currently being undertaken by its India business.

“We’ve completed 30 months of a five-year continuous maintenance contract (CMC) with the world’s largest grassroots refinery located in Jamnagar, India,” he explains, “providing daily plant maintenance services to 17 units within the refinery.

“This includes the completion of 12 shutdowns and turnarounds this year alone, a period in which we’ve achieved almost 1.3 million safe working hours.”

Meanwhile, the company’s Malaysian unit recently secured a 10-year contract with Petroliam Nasional Berhad (PETRONAS) to uphold daily maintenance and turnaround activities at its Pengerang Integrated Complex, and its Thailand business has been working with Shell Brunei to remove a partially collapsed storage tank roof – again completed safely and in line with customer demands.

These are just a handful of key examples, however, and CR Asia’s pipeline looks equally impressive.

“We will be significantly involved in the next major turnaround for Star Petroleum Refining Public Company (SPRC) in Thailand, scheduled for November 2019,” Young continues. “It’s a project we’ve been planning for approximately two years, with a total scope of 130 tonnes of fabricated steel structure, 25 vessels, eight columns and 225 items.

“We’ve begun to develop mock-ups, the idea being that our teams will carry out mechanical maintenance works on the crude distillation unit (CDU), vacuum distillation unit (VDU), platformer and fluidised catalyst cracking unit (FCCU).

“Our Special Services division will support both project and maintenance works with ultra-high-pressure water jet cutting (UHPWJ), diamond wire cutting, bolt torqueing, pipe cutting and flange machining, and the catalyst and high-pressure cleaning divisions will work on change-outs and cleaning work throughout the entire event.”

The company’s Thailand and Malaysia divisions have similarly exciting prospects on the horizon, the former looking to secure further projects at the Nghi Son Refinery in Vietnam, with the end goal of creating a new joint venture with a local enterprise to expand the company’s footprint in the country.

The latter, meanwhile, remains focused on the integrated refinery and petrochemical plant in Pengerang, Johor, its sights firmly set on adding to its existing term contracts.

Equally, projects are not the only evidence of CR Asia’s success, the company similarly establishing itself as a spearhead of industry innovation.

The firm has embraced industry 4.0 and bolstered the overall efficiency and capabilities of its operations, leveraging technologies such as Rover – the name given to its remotely operated, multi-purpose tracked vehicles – which were developed to reduce and even eliminate the risks involved in entering confined spaces when removing catalysts from reactors and cleaning vessels.

“These next-gen solutions help to improve safety by greatly minimising the need for our technicians to enter confined, hazardous or even underwater spaces and also have a positive impact on project schedules,” Young affirms. “Remotely operated vehicles don’t need the same regular rest breaks that technicians do and can start jobs earlier due to the fact they can withstand temperatures of up to 100 degrees Celsius.”

Evidence of the fruits of these investments comes once again from CR Asia’s Thailand enterprise, its remotely operated equipment having secured the company a long-term contract for removing spent adsorbents with Chevron.

Further, advanced wet dumping technology has proven to be a similarly coherent investment. Based on a number of proven technologies, the firm has successfully commercialised its usage in Asia.

“Advanced wet dumping is a process for removing extremely hard materials from reactors such as coke or fused catalyst,” Young explains. “Traditionally, removing these rock-like materials has been problematic. But our solution combines drilling technology with high pressure water to remove over 90 percent of the hardened material in less than a quarter of the time without having to enter the reactor.”

The in-house design, build and commissioning of drum tippers to increase the speed of emptying drums, the development of its own dense loading technology to deal with various catalysts and a range of semi-automated internal and external bundle cleaning equipment are also key investments that the firm has pursued of late.

And its geographical footprint has been enhanced in tandem.

In late 2016, for example, the business held an opening ceremony for its new Thai workshop, a 2,000 square metre structure equipped with a five-tonne overhead crane. And less than a year later, it also completed work on the new Thai office building which is now used by around 70 staff from CR Asia’s operating department.

Meanwhile, in India, the organisation is in the process of opening a new purpose-built facility and training hub in Jamnagar, costing around $1.5 million. And in Malaysia, the company has acquired premises near to the new integrated refinery and petrochemical complex in Johor, set to become a three-acre facility and a key hub in that territory.

While this emphasis on technology, equipment and facility is key to the firm’s competitive advantage, so too is its esteemed workforce – something that Young is quick to iterate.

“People are the core of our business,” he declares, affirming this statement by pointing to CR Asia’s extensive training programmes.

Ensuring it instils best practices across the board, the firm has invested substantially in the development and operation of two large dedicated training facilities in Rayong, Thailand and Jamnagar, India. Both developments provide certified, tracked and managed supervisory, safety and trade-based validation services for all staff which adhere to three core principles – measurability, relevance and reliability.

“Continuous improvement is part of the very fabric of CR Asia,” Young adds.

“We establish key performance indicators for all and targets to drive employee development. In turn, the business benefits on all fronts.

“We find that this continuous commitment to improvement is similarly reflected in many of the projects that we complete in record time for our customers at lower costs and with higher quality,” Young continues. “We’re always investing in and developing smart systems and performance management tools to support our personnel in delivering responsive and innovative services.”

One such example is the soon to be group-wide ERP system, introduced in April 2018.

Initially implemented at CR Asia Thailand to ensure the effective management and operational control of all projects as the company continues to grow, taking on new, increasingly complex contracts at scale, it will now be rolled out across the group by 2020.

“The system, Epicor, is cloud-based, meaning all parties can access relevant data much faster and more reliably to improve decision making processes,” Young states.

“It’s taken some time to get used to, but functions as intended. And we were even nominated and awarded the Epicor Customer Excellence Award for Cloud Deployment – the prize for which we used to provide a $500 donation to a local school in the Rayong area for school uniforms.”

As this donation suggests, CSR is indeed another key focus for CR Asia Group.

Its social responsibility strategy is driven by local committees within each business, ensuring the company provides targeted, relevant assistance to deliver real benefit to local people.

Young reveals: “We proactively engage with the communities in which we work.

“Our programmes are usually focused on the delivery of healthcare and education for children, and the development of local infrastructure. No matter the initiative, we encourage our staff to uphold the delivery of these programmes, ensuring the creation of a powerful link between community and company.”

Owed to these efforts, the enterprise also received the Corporate Social Responsibility Award from the Department of Industrial Works in recognition of CR Asia Thailand’s commitment towards operating in the right way, graded against a criteria including organisational governance, human rights, labour practices, environmental practices, fair operating practices, consumer issues and community involvement.

Yet this award should come as no surprise, the company able to call upon numerous examples of similarly admirable stewardship.

And Young does just this when prompted: “Due to the collapse of the Xe Pian-Xe Namnoy dam under construction in the southeast of the Lao People’s Democratic Republic in July, several villages were completely washed away and many more were flooded, forcing thousands of people to evacuate.

“We felt a strong empathy with the flood affected people in Laos and Cambodia and their urgent need for help, so CR Asia Thailand approached the Rayong Safety Association to rally relief support for the victims through donations of food, clothing and other essential items to survive.

“Meanwhile, in Thailand we sponsored the 2019 DOW Charity Run and provided drinking water for all runners. 10 employees joined the five-kilometre fun run held in June 2019, at Lumpini Park in Bangkok that drew over 1,200 participants. This year’s event promoted environmental conservation and raised funds for the Thai Red Cross Society’s Repair of Cleft Lip and Cleft Palate and Other Deformities Project.”

Impact investment, technological innovation, employee excellence and an esteemed, ever-growing project portfolio combined, the future looks bright for CR Asia Group.

Executing all projects safely, on time and within budget, the firm is anticipating 40 percent growth this year – a spurt that will pose both new challenges and opportunities alike.

“Every few years we take our operations to the next level,” Young affirms, “and this is set to be one of those periods, an advance that we’re preparing to sustain and build on for years to come.”

Yet growth is not the only company’s ambition. Indeed, the opportunity for further diversification is similarly on the horizon – a window that the Group Business Development Manager eludes to in his concluding statements:

“We’re looking forward to finding additional ways to enhance our business in terms of adding new service lines and focusing on new territories.

“We have a strategy event planned for the latter stages of 2019 when the senior management of the company will come together to discuss and agree where our next wave of prosperity is going to come from in advance of conducting our next business planning cycle to 2023 and beyond.

“It will certainly be interesting to see what occurs on the horizon during this next crucial period.”