By providing access to real data, digital twins enable Indonesian operators to have eyes on assets and operations that are thousands of kilometres away. Raj Kaushal, Senior Business Development Manager for APAC at James Fisher AIS, explains.

MAKING THE INVISIBLE VISIBLE IN INDONESIA’S ENERGY INDUSTRY

Nestled amidst the equatorial seas, Indonesia emerges as a mesmerising archipelagic state.

Amongst a sprawling tapestry of over 17,000 islands lies an energy-rich heart, where geothermal power is drawn from the Earth’s core, and ocean tides beckon as an untapped source of renewable potential.

It also has a rich oil and gas heritage, with production peaking in the 1990s.

However, over the last few decades, the country has faced challenges such as declining reserves, aging oil and gas infrastructure, and regulatory issues, leading to a decrease in oil production and a shift towards natural gas as a lower emissions alternative.

Oil and gas will continue to play a major role in Indonesia’s varied energy portfolio, ensuring domestic energy security, but to continue to do so, certain challenges will need to be addressed.

The decline in production is owed to the country’s particular set of challenges, such as investment frameworks, field development solutions, and the balance between national and private entity interests. Introducing digital solutions that deliver increased efficiencies can therefore prove to be challenging.

DIGITALISING THE ARCHIPELAGO

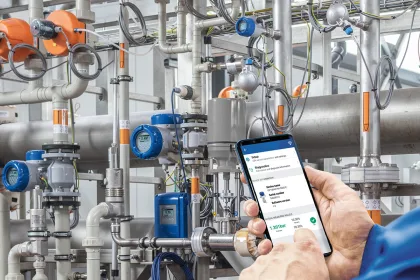

However, digitalisation could provide a solution to a sector filled with data silos. Digitalising operations can bring a whole host of benefits such as reducing asset downtime and improving worker productivity and on-site execution, by bringing together data that helps to paint a vivid picture of an asset’s real-time status.

In Indonesia, assets are typically in remote locations with limited data connectivity. Modern digital systems can support the integration of data to allow engineers and managers to visualise the reality of the situation without wasting time gathering data. These systems can bring together asset data from the most remote corners of the country, helping local oil and gas companies, as well as government entities which provide support and funding, to better understand the safety and operating status of energy hubs and assets.

Digitalised data is vital when dispersed teams are operating on the ground in different locations; it can help to bring the disparate islands of the archipelago together.

Digital solutions providers across the islands can help Indonesian energy producers access enriched views of their assets through centralised, digitalised systems of data management. Pinpointing exact anomalies, faults, and risks, this real-time overview of an aging infrastructure, in remote and unforgiving environments, can plug the gaps in operations.

Newer technologies like digital twins mean Indonesian operators can access reality data to monitor assets and operations across the archipelago. Through this, the pre-planning of maintenance, as well as the delivery and quality assurance of major projects, plays a large role in the broader regional energy context.

For Indonesia’s aging infrastructure, digital twin software models which connect site imagery to existing data could provide significant opportunities to maximise output as the assets degrade.

BUILDING RELATIONSHIPS TO FOSTER GROWTH

Whilst digitalisation might plug the gaps and connect the dots, companies can be wary of taking a risk of investing in the search for a return on investment.

However, the opportunity to deliver more value from assets remains. By partnering with software companies – those with local, geographical, and historic knowledge of sites – to support exploration, drilling, and production, national oil companies and smaller, local energy producers in Indonesia can find their operations vastly maximised.

More from APAC Outlook

Hesitancy to change can arise in the face of energy security concerns. As such, digital solutions providers looking to make headway in the region need to adapt their approaches, build bridges with flexibility in mind, and consider local nuances.

Historically, long-lasting partnerships across the industry have been fostered through consultative-style processes. Through this, confidence is built, trust is instilled, and progress is made. By being adaptable, Indonesia’s oil and gas companies can have confidence in adopting innovative digital technologies by making smaller changes in the first instance, and then scaling that success.

This model could mean that Indonesian energy companies are keener to adopt advanced technologies like data analytics and predictive maintenance, ultimately bolstering their operations. With this growth, seeing a return on investment should instill further confidence in these partnerships and technologies, giving Indonesian firms the option to scale operations and adoption.

And the proof has been in the pudding. With digital twins providing access to real data, Indonesian operators have eyes on assets and operations 3,000 kilometres away, making the invisible, visible. This has already been done at a remote LNG production facility in Indonesia, where James Fisher AIS’ R2S digital twin meant that the team could cut down on over 20 hours of travel time to reach the facility from the nearest hub city, as well as increase collaboration across the dispersed team.

LOOKING TO THE FUTURE

Indonesia has clear ambitions to grow its energy industry across multiple sectors and bolster its power generation.

With agreements in place to export clean energy to Singapore, and recent progress made in prioritising natural gas and geothermal energy, less carbon-intense energy sources also have a part to play in both the energy transition and energy security of the region.

Across oil and gas, geothermal, and natural gas, it’s clear that digital solutions and flexible business models which put energy companies and their pain points first will be key to achieving these.